Advantages

Research & Development System

Zopoise Technology Co. Ltd has devoted itself to technology innovation, invested capital and in personnel, hired experienced Optical, Electrical, Mechanical, Material and Test Engineers. We have focused on environmentally friendly intelligent lighting solutions. Zopoise Research and Development Center contains the R&D Institute which focuses on new product and development, Application Research, Project Management, Industrial Design, and Technological Support. This creates an excellence in technological research and development of LED Lighting.

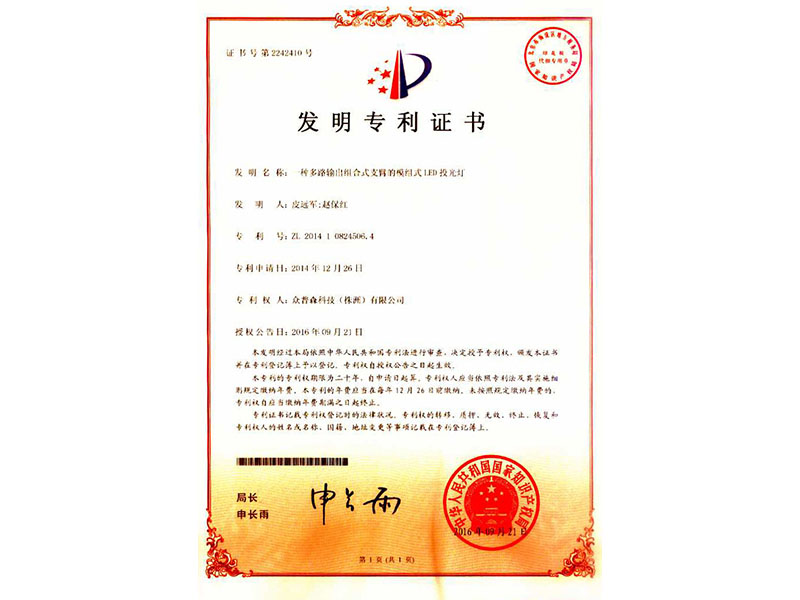

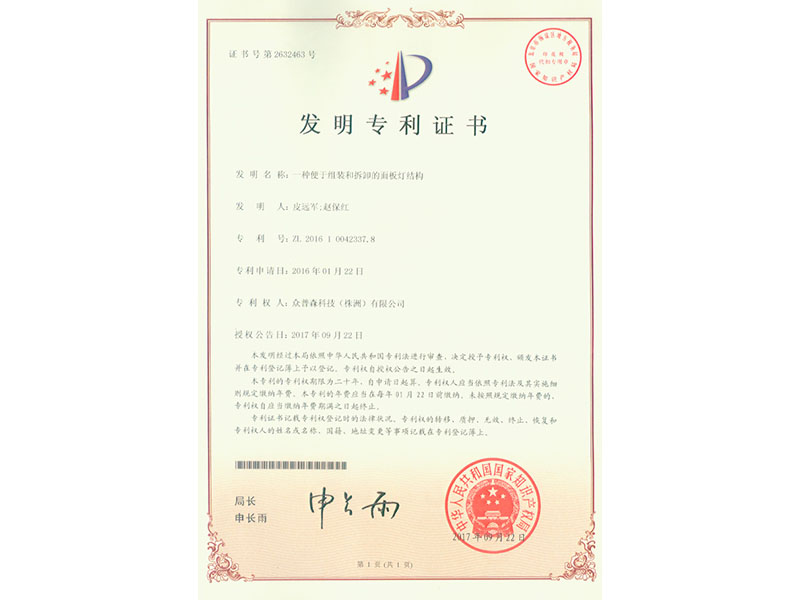

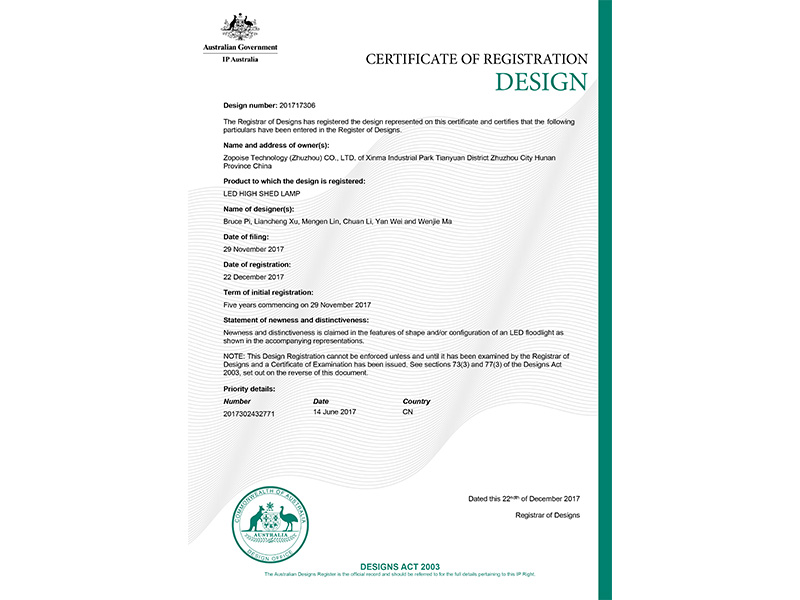

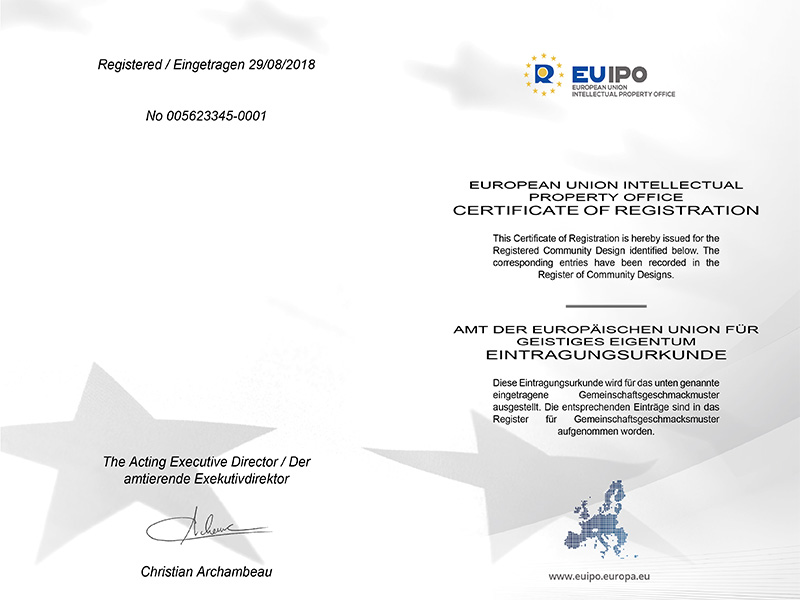

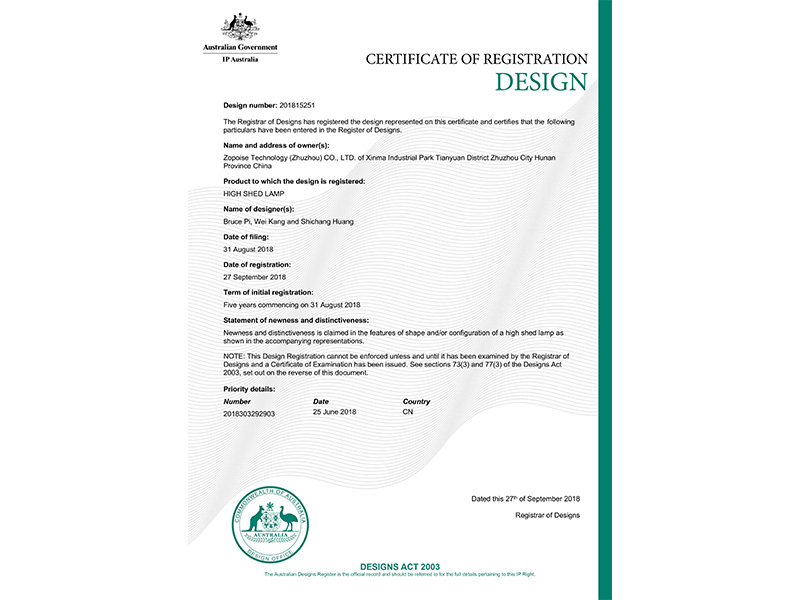

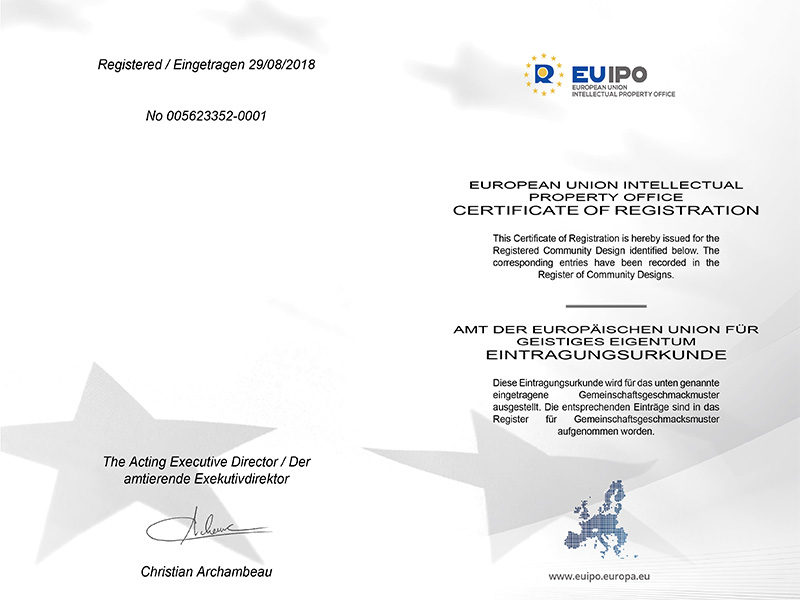

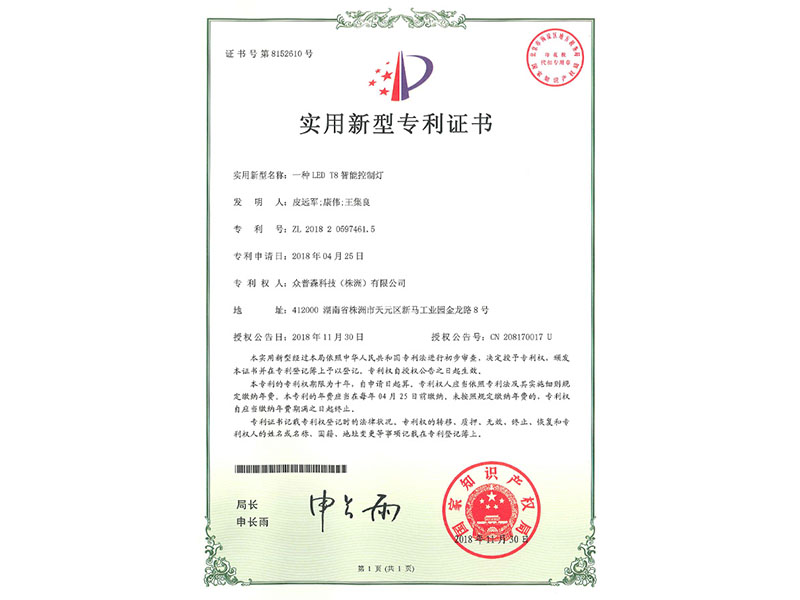

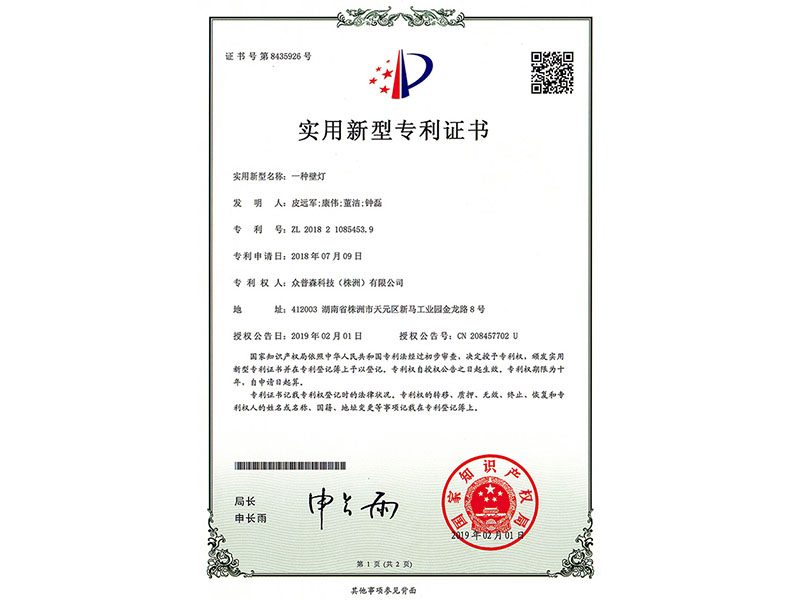

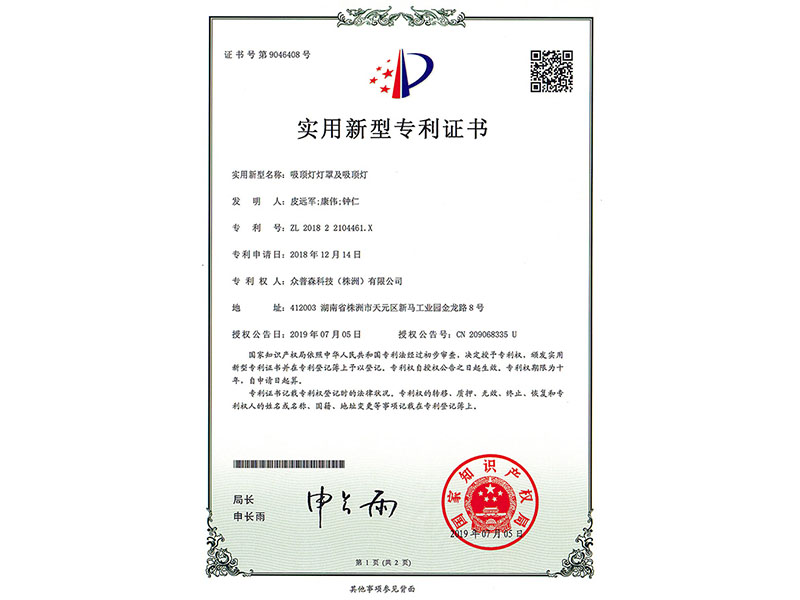

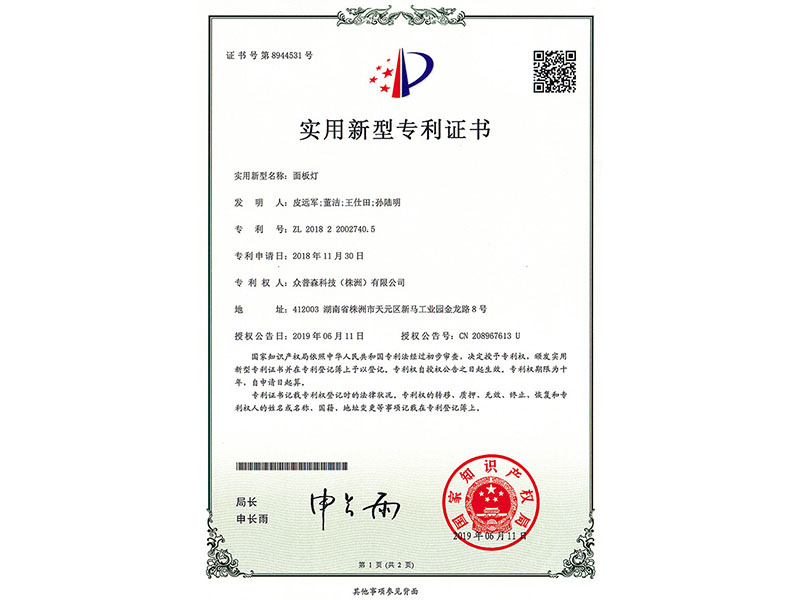

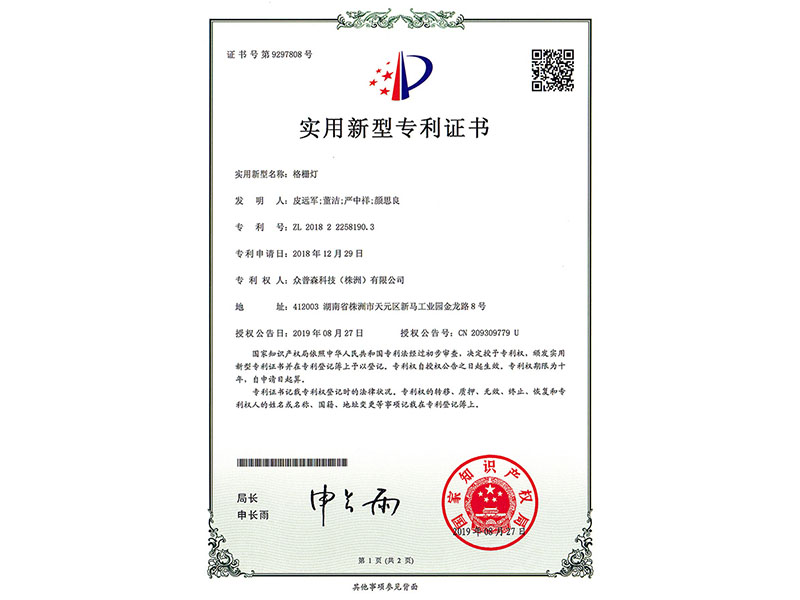

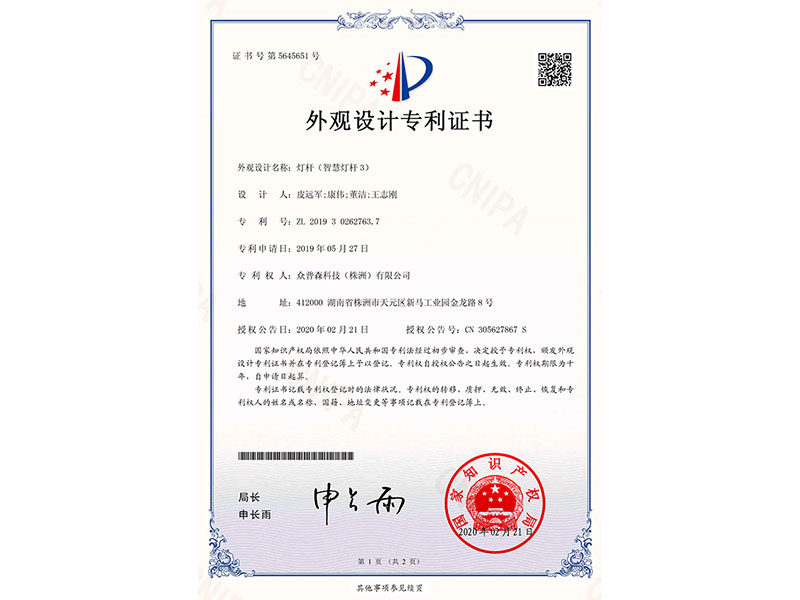

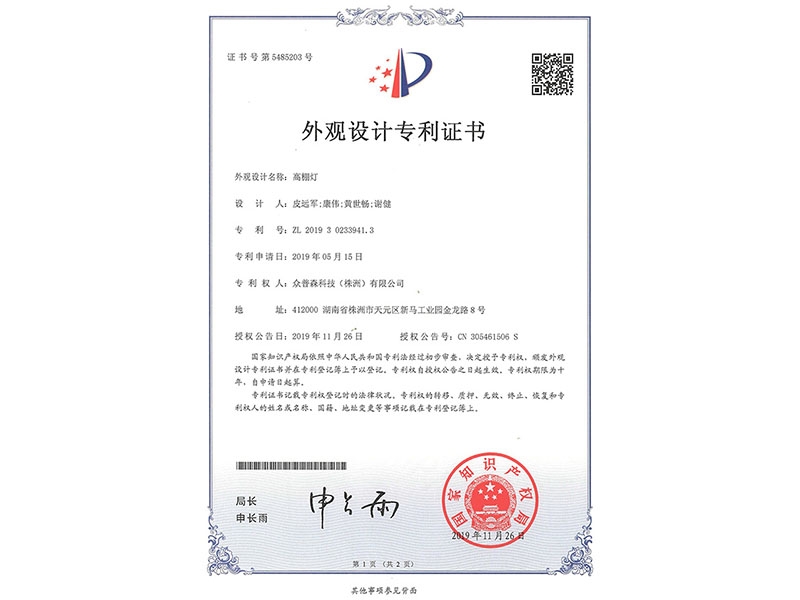

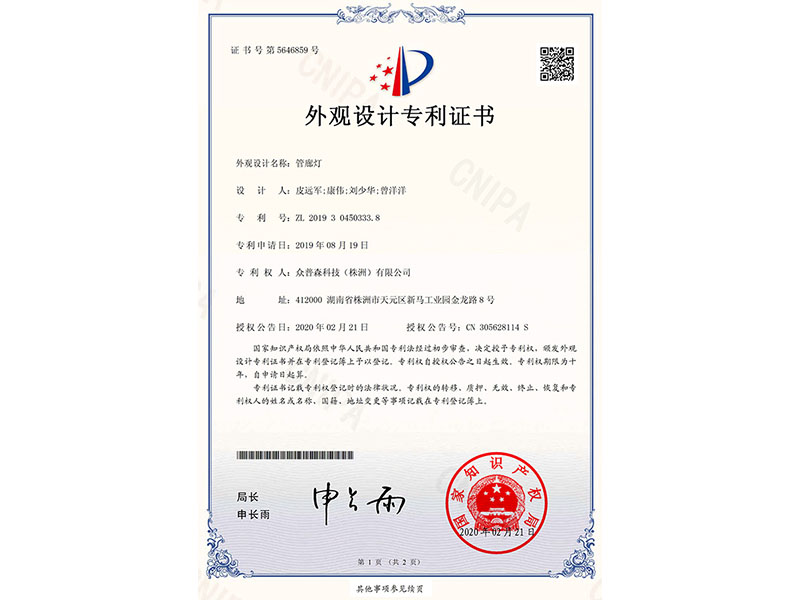

Zopoise has invested in technology innovation and is continuing its innovation to support clients’ requests. Zopoise has been awarded nearly 700 patents which include Technology Innovations, Utility Patents, Design Patents and Software Copyrights.

Within the new layout of product development and supply chain, Zopoise always sticks to technology innovation, continually striving to build on economies of scale and cost advantages, to achieve an industry upgrade from Made In China to Innovated by China.

Innovation is the backbone to brand vitality. Innovation is the soul of an enterprise.

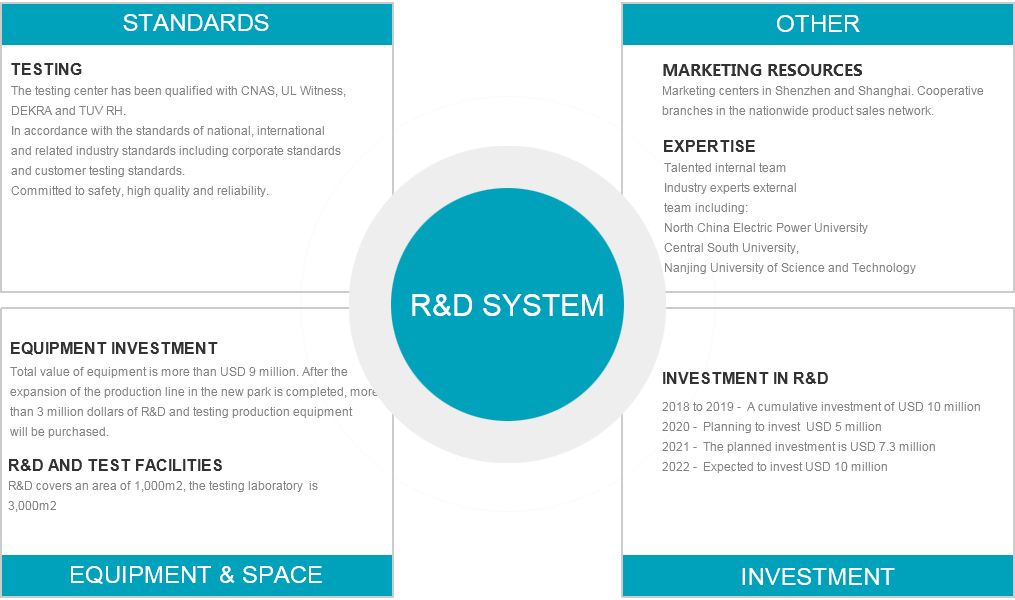

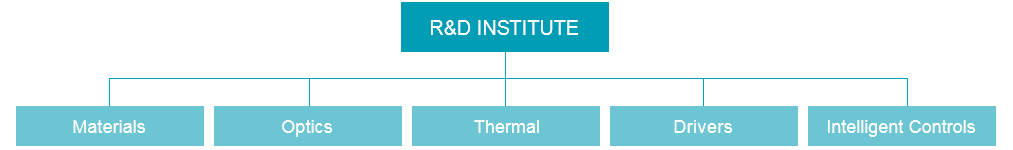

Zopoise Research and Development System

The Guarantee Conditions of R&D System

Zopoise Technology R&D Institute

The research focus of Zopoise R&D Institute:

Basic research of LED lighting and its' components including the fields of Materials, Optics, Thermal Management, Light Sources, Drivers, Intelligent Controls, Construction and Industrial Design.

The main research topics of Zopoise R&D Institute are:

1、

Research on Modularization, Modularization Application and Standardization Interface Technology of LED Semiconductor Lighting.;

2、Application and technology of new materials, new processes and new technologies in the construction, electrical, heat dissipation and light distribution of LED light sources and fixtures.

3、System integration of Intelligent Controls based on WiFi, ZigBee and other technologies in LED lighting applications.

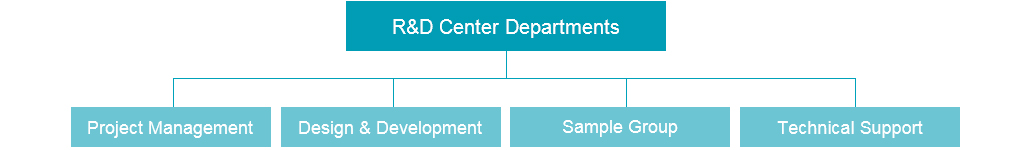

Zopoise Research and Development Center

The Zopoise R&D Directive:

LED lighting product design and development, as well as innovative technologies such as: new materials and new processes, are applied to the research and development of LED Luminaires. The products developed by Zopoise are products for various applications including Commercial & Industrial Lighting, Landscape and Traffic Lighting. We also develop light sources and self-ballasted reflector lamps.

The current LED product offering includes products for many applications: Roadways, Areas, Tunnels, High Bays, Gas Stations, Panels, Down lights, Ceilings, Canopy lights, T8 Tubes, Linear Lights, Floodlights, Wall Washers, Point lights.

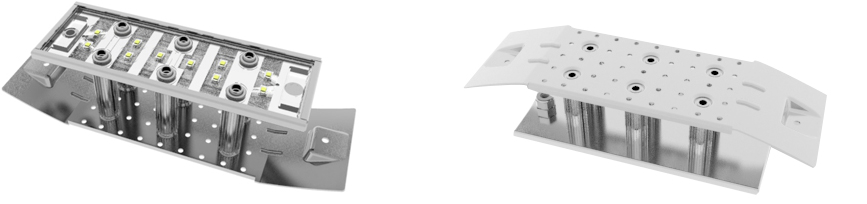

Product Innovation

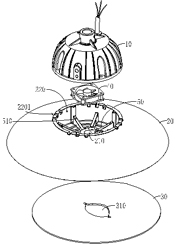

Application of enhanced cold and hot air convection structure

The built-in exhaust fan enhances the convection of hot and cold air, thereby improving the efficiency and reliability of the heat dissipation.

Application of glass housing and heat dissipation

Glass replaces the metal housing, breaks through traditional materials and processing technology, better weather resistance.

Quick and easy assembly.

Excellent cost reduction opportunities.

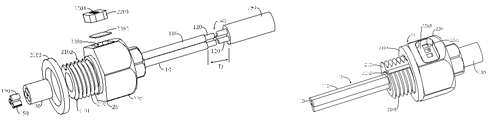

Application of integrated wire for anti-siphon with breather

Combination design of a waterproof connector, breather and electrical wire.

Simple assembly, three parts are simplified into one part.

Lower material and production costs.

Graphene composite

Utilize a Graphene composite material which has high thermal conductivity properties and is chemically stable. This invention allows us to lower material and assembling cost.

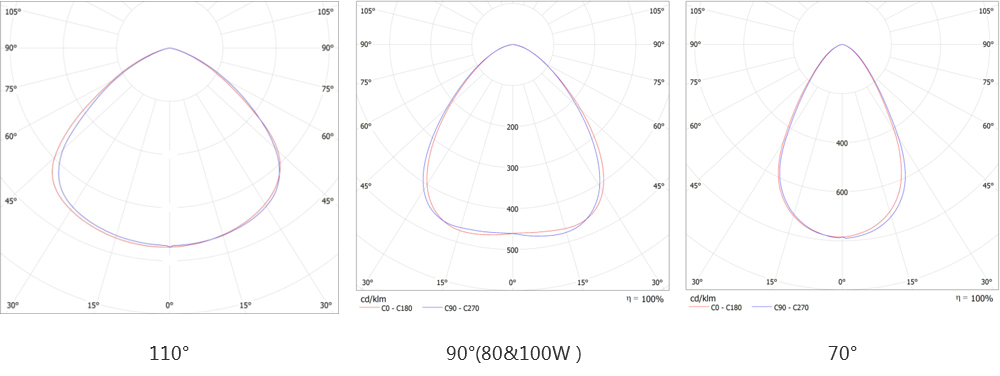

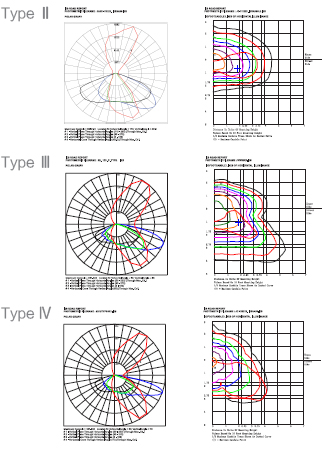

The application of distribution technology with wider application and higher usage efficacy

Based on the basic calculation of road brightness, relax the edge diffusion control while ensuring the anti-glare performance, and effectively reducing the road surface "zebra effect" A new optical innovation which reduces glare and improves light control and easily adapts to different distribution types while increasing optical efficiency.

Street light optical design principle

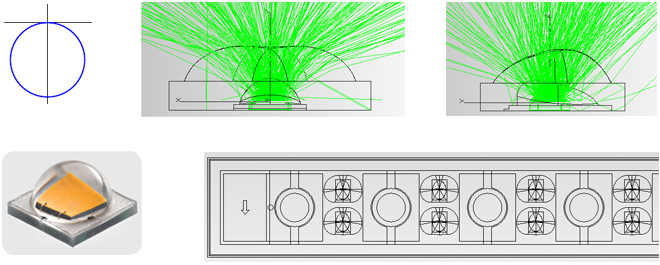

Application of anti-glare, asymmetric reflector light distribution technology

LEDs is semi-hidden, the light of the smaller light intensity part of the direct emission, while the light of the larger light intensity part of the reflection of the surface under the reflector will become indirect lighting, both to improve the utilization of the light pass and effectively suppress the direct glare.

The light outlet is designed to increase the area of the light outlet, effectively eliminating the visual discomfort caused by the strong directivity of LEDs.

Textured glass lampshade, smooth texture surface, more corrosion resistance, easier cleaning, and higher light transmittance than ordinary frosted glass. Anti-glare effect of textured glass is particularly obvious.

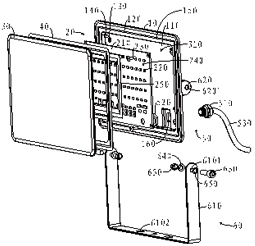

Application of screw-less riveting flanging sealing technology

No pre-drilling or tapping required, saving processing costs.

The module does not require any other fastening parts, saving material costs.

The light source cavity is sealed by aluminum riveted and crimped edges with IP67 protection.

Mechanized automatic assembly without any manual operation, greatly improves assembly efficiency while eliminating human error.

Research center

Intellectual Property

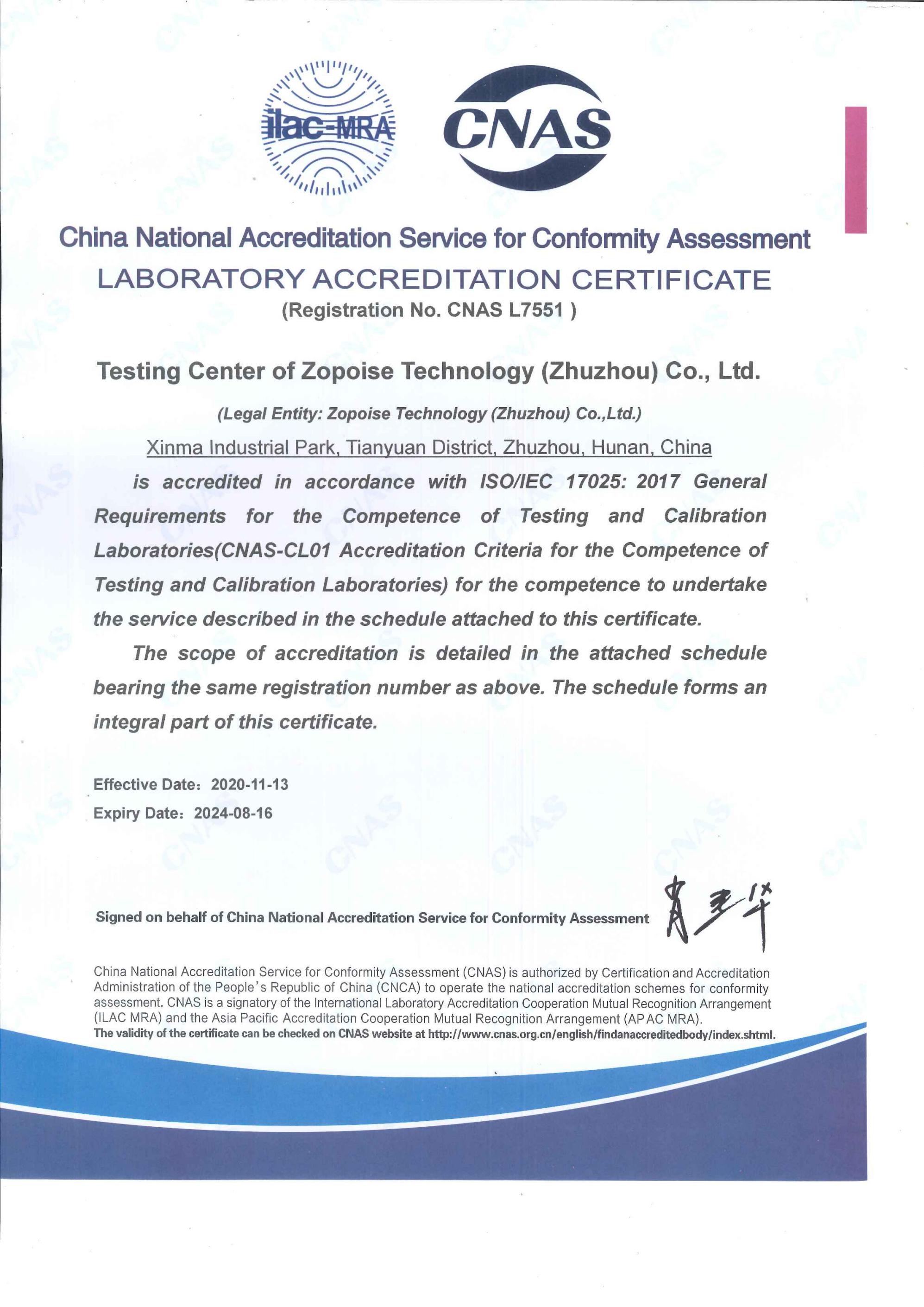

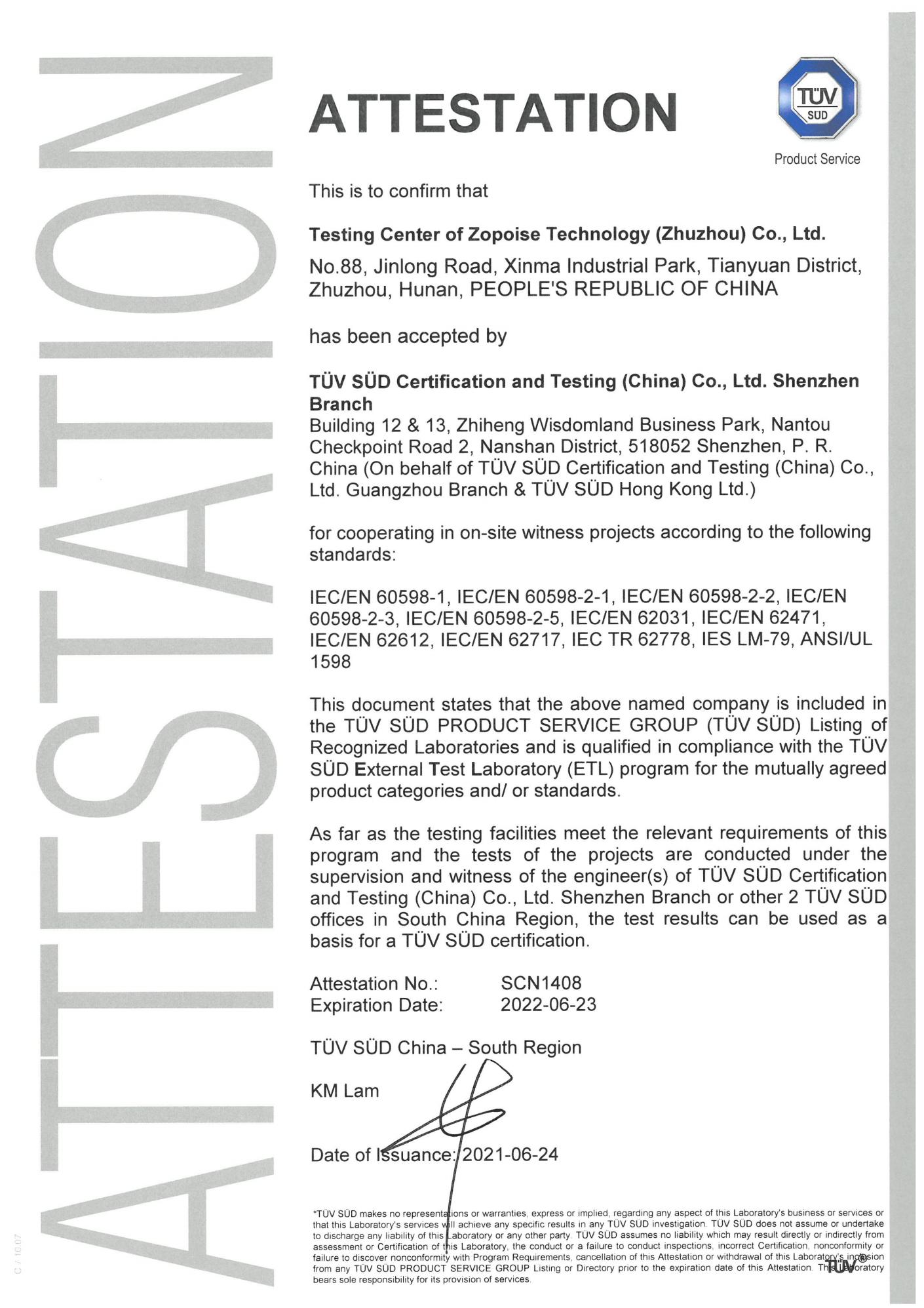

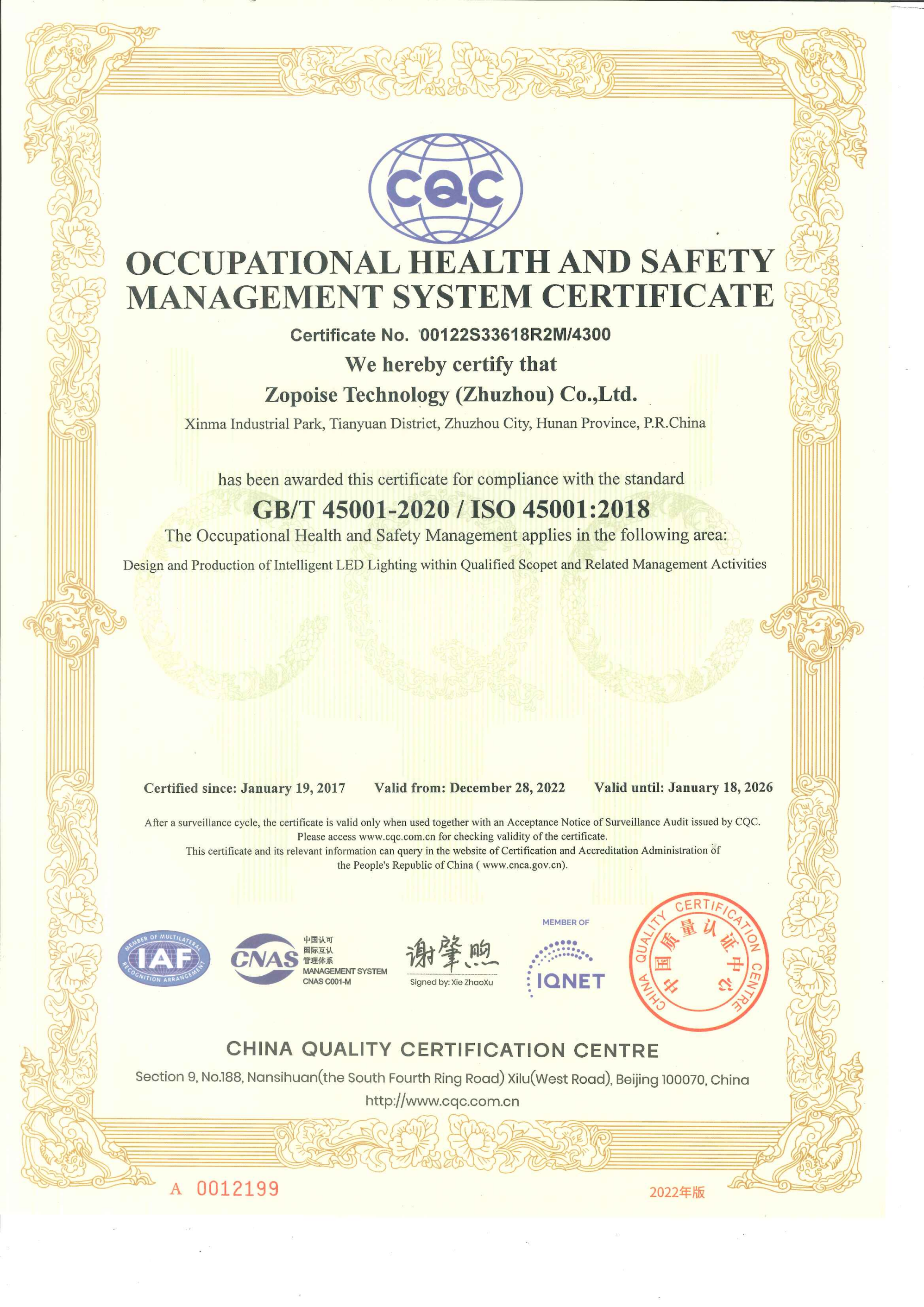

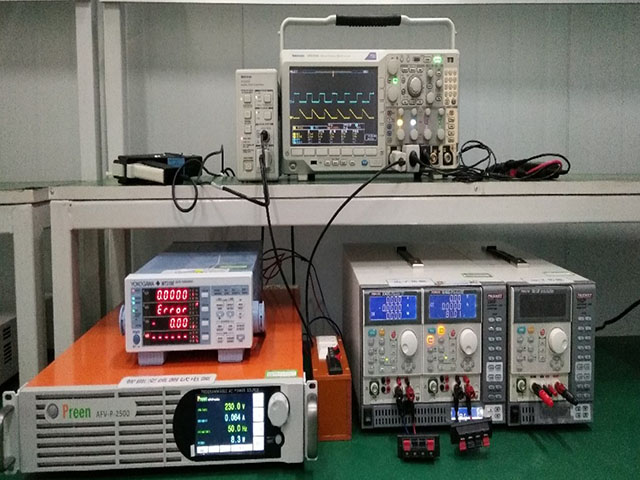

The Zopoise Technology Testing Center, located in Zhuzhou, spans an area of more than 3,000 square meters, it is equipped with advanced testing equipment such as Everfine, Tektronix, Fluke, Agilent, and Rohde & Schwarz, with a total investment of USD 4.5 million. It includes test laboratories in the fields of Safety, Optical, Optical Radiation Safety, Outdoor Protection, Materials Testing, Reliability Testing, Electromagnetic Interference and Testing, ERP Aging and other experimental testing areas.

The various laboratories are dedicated to Research & Development, Testing and Safety of Luminaires and Lamps, Materials Testing, Power Supplies Development and Quality Assurance. The laboratories are also valuable to reduce the time to market and supporting our customers’ needs.

The Testing Center conducts testing in accordance with international standards such as the IEC, EN and Underwriters Laboratories (UL), GB country and industry standards, and enterprise standards. It operates in accordance with the ISO/IEC 17025, the international standard for testing and laboratory management system. The testing center has maintained long-term technical cooperation with internationally renowned certification bodies. It has been accredited by the China National Accreditation Service for Conformity Assessment, CNAS and has obtained the American UL Witness Test Data Program, German TÜV RH, TÜV SÜD and German DEKRA witness certification laboratory qualifications, as well as DEKRA CBTL laboratory qualifications.

Testing Accreditations

Testing and Reliability

Performance Testing

Starting Voltage & Current, Operating Voltage & Current, Surge Protection, Total Power, Power Factor, Driver Current, Abnormal Test, Thermal Test, Driver On/Off, Overall Performance

→

Optical Testing

Lumen Output, Light Intensity Distribution, Beam Angle, Efficacy, Color Coordinate, Correlated Color Temperature – CCT, Color Rendering Index - CRI

→

Safety Inspection

Construction and Assembly, Proper Markings, L-N-Ground, Proper Grounding, IP Testing, Insulation, Protective Conductor Current, Creep Age Distance, Electrical Clearances, Durability, Heating, Heat Resistance, Combustion Resistance

→

EMC Inspection

Interference Voltage, Radiation Interference, Electrostatic Discharge, Surge, Fast Transient

→

Material Inspection

Hot Wire, Flame, Electrical Leakage, Marking, Ball Pressure, Combustion, IK Impact, Wire Swing

→

Reliability and Failure Analysis

Destructive Physical Analysis, Reliability Analysis, Temperature Cycling, Power Switch, Accelerated Life, Temperature Shock, Constant Humidity Heat, Elevated and Low Ambient, Low Temperature Startup

→Manufacturing System

Our manufacturing process is fully vertically integrated. From key raw materials, Die castings, Drivers, Controls, Luminaires and Lamps assembly. This capability has created a fast-response manufacturing system enabling us to meet the needs of our customers. In addition, our manufacturing has automatic intelligent production lines that can easily produce large quantities with high efficiency. Production lines are equipped with automatic intelligent robots and online monitoring. The product quality rate is over 99%.

The system is easily convertible for small batches and multiple variations of the product. Our company's ERP and MES systems run through the entire manufacturing process, with constant automatic monitoring, collection and analysis of production data. This ensures high efficiency and high quality of the production and manufacturing of our products.

Zopoise Technology Manufacturing System

SMT

Automatic SMT production line from Japan.

Fully Automated Intelligent Production

Robotic intelligent operation, online monitoring.

Fully automated production of aging room and water bubble room.

Real-time cycle monitoring of product testing including temperature, safety, vibration/shock, accelerated aging and IP waterproof/dust test.

ERP and MES systems run through the entire production process.

Automatic date collection and analysis of the whole product manufacturing cycle.

Lean Production

Small quantity unit production capabilities, the change-over is extremely flexible and fast.

Workers are proficient in a variety of tasks and production lines.

Experienced in the production of small batch and multiple variations of products.

Quickly respond to market changes and customer requirements.

Die Casting

3 central furnaces and 28 die casting machines from 280 tons to 1600 tons.

50 CNC machines, and 5 automatic powder painting lines.

The production capacity of casting, process and surface treatment with an annual output of 100,000 tons.

Plans to invest in the Tooling manufacturing workshop to further expand our capabilities.

Sensor Manufacturing

Imported SMT equipment.

Al automatic plug-in machine, automatic assembly line, automatic aging room, automatic test system.

ERP, MES, PLM system management is implemented maximize production of reliable and cost-effective drivers and sensors.